Our Core Advantages

Integrated E2E Solutions

Seamless Process Integration:

Closed-loop control from concept to delivery

Al-Infused Innovation

Cross-domain Convergence:

Evolutionary synergy of hardware-algorithm-cloud

Proven Customization

Delivering end-to-end tailored solutions for leaders across 40+ industries

Certified Quality

Six Sigma x Auto-QC:

≥99.98% yield rate in mass production

Stage 1: Strategy & Product Definition

Transform business objectives and market opportunities into a clear,

actionable blueprint for successful product development.

Uncovering Opportunity: Mapping Your Path to Market Success

Through in-depth market and user research, we pinpoint competitive landscapes and user pain points to identify the most valuable business opportunities. This initial step provides a data-driven map to success, ensuring your project is engineered for market fit from day one.

✅ Competitive Analysis: Assess rivals’ products, strategies, and market impact

✅ User Personas: Profile target users’ traits, behaviors, and core needs

✅ Market Gap Analysis: Identify unmet opportunities via tech trends and user insights

Focusing on Value: Architecting the Core Product Experience

We collaborate with you to distill the product’s core features from all possibilities, ensuring each one targets key user needs and delivers maximum value. This process builds the product’s experiential backbone and competitive moat, setting a clear focus for all subsequent R&D efforts.

✅ Feature Brainstorming: Divergently generating all potential product features based on market research

✅ Prioritization Matrix: Using methodologies like MoSCoW to classify features into tiers

✅ USP Definition: Clearly defining the key unique values that differentiate the product

Solidifying the Blueprint: Translating Vision into Engineering Language

We document all functional definitions, metrics, and acceptance criteria in a Product Functional Specification (PFS). This “project constitution” ensures team alignment and serves as the foundation for quality assurance.

✅ Detailed Functional Description: Providing granular written and logical descriptions for every feature

✅ Quantitative Performance Metrics: Defining clear parameters like response time, speed, and power consumption

✅ User Flow & Exception Logic: Mapping user journeys and foreseeable exception handling procedures

De-risking Innovation: Ensuring a Robust Implementation Path

Before R&D commitment, our engineering team reviews the PFS for technical feasibility, assessing technology maturity and supply chain risks. This proactive approach “de-mines” potential issues, ensuring your vision is both innovative and achievable.

✅ Core Tech Stack Assessment: Analyzing maturity and suitability of required software/hardware technologies

✅ Key Component Review: Evaluating performance, cost, and supply stability of critical components

✅ Bottleneck Prediction & Mitigation: Identifying major technical challenges with preemptive solutions

Stage 2: Design & Engineering R&D

Translate product blueprints into complete, production-ready

hardware/software engineering solutions.

Sculpting the Sensory Experience, Defining Product Appeal

Our industrial designers transform brand values and user needs into compelling physical forms, balancing aesthetics, ergonomics, and usability. This ensures your product looks exceptional and delivers intuitive, delightful interaction from first touch.

✅ Concept Sketching & Rendering: Explore designs through sketches and photorealistic rendering

✅ Ergonomic Optimization: Optimize product form using hand models and usage scenarios

✅ CMF Definition: Define Color/Material/Finish to build brand identity and emotional connection

Engineering the Physical Form, Ensuring Production Readiness

Our mechanical engineers convert industrial designs into robust, manufacturable structures. We optimize component layouts, enclosures, and assemblies for performance, durability, and cost-effective production.

✅ Internal Component Layout: Optimize component 3D arrangement for thermal & signal performance

✅ Material & Structural Analysis: Validate materials and strength via FEA

✅ DFM Integration: Apply DFM principles for high-yield mass production

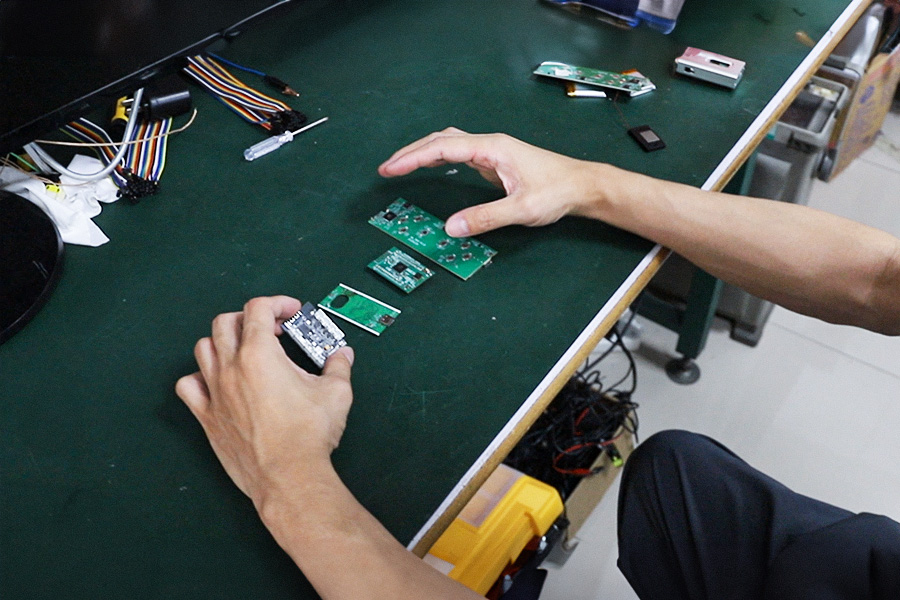

Forging the Electronic Brain & Central Nervous System

We design custom PCBs and embedded systems as the product’s electronic core, ensuring peak performance, power efficiency, and stability. This involves precise component selection and schematic layout to build a robust software platform.

✅ Component Selection: Select key components by performance, power, cost & supply chain

✅ Schematic Design: Convert functions into error-free circuit logic

✅ PCB Layout & Routing: Multi-layer layout for signal integrity & EMC

Injecting the Intelligent Soul, Delivering the Full AI Experience

Our engineers develop all software layers—from hardware drivers to custom apps and AI algorithms. This seamless hardware-software integration delivers the intelligent, responsive experience in your vision.

✅ Firmware & Driver Dev: Build stable firmware & drivers for seamless OS-hardware communication

✅ Custom App Development: Develop responsive apps to deliver core product value

✅ AI Integration & Optimization: Deploy optimized AI models for max intelligence with min power

Stage 3: Validation, Testing & Refinement

Through systematic and phased rigorous testing, ensure the design

solution’s maturity, reliability, and manufacturability.

Laying the Foundation: Core Engineering Validation (EVT)

In the EVT phase, we transform engineering blueprints into physical prototypes for the first time, focusing on verifying the correctness and feasibility of the core electronic functions. The goal of this stage is to discover and resolve fundamental hardware design flaws early, ensuring the product’s “heart” beats as intended.

✅ Basic Functional Verification: Verify power-on, boot-up & interface electrical characteristics

✅ Key Module Testing: Validate CPU, sensors & wireless modules functionality

✅ Hardware Defect Debugging: Fix critical schematic & PCB flaws for phase stability

Forged in Fire: Comprehensive Design Validation (DVT)

In the DVT phase, we use near-final prototypes to conduct comprehensive “stress tests” under harsh conditions, validating the overall design’s reliability and durability. This stage aims to ensure the product is not only fully functional but can also withstand the complex challenges of real-world use.

✅ Performance & Power Testing: Conduct system benchmarks & power analysis

✅ Environmental & Reliability Testing: Execute temperature, vibration & drop endurance tests

✅ Compliance Pre-testing: Pre-test EMC, RF & safety for market regulations

Locking in Excellence: Production Readiness Validation (PVT)

In PVT, we execute the first trial run on final production lines, focusing on manufacturing validation. This confirms the factory’s ability to mass-produce our design with consistent cycle time, controlled cost, and stable quality.

✅ Line Yield Assessment: Monitor FPY to resolve mass production bottlenecks

✅ SOP & Tooling Validation: Validate SOPs and finalize production fixtures

✅ QC Process Finalization: Establish IQC/IPQC/OQC standards & testing

Defining Replicable Success: Finalizing the Manufacturing Blueprint

This finalizes hardware development, locking down the validated BOM and process parameters. The result is an error-free “manufacturing recipe” ensuring every unit matches the golden standard.

✅ BOM Freeze: Freeze validated part numbers, specs & suppliers

✅ Process Flow Finalization: Solidify manufacturing & testing steps from start to finish

✅ Key SOP Lock-in: Define and lock critical station parameters in SOPs

Stage 4: Mass Production, Delivery & Lifecycle Support

Achieve efficient, high-quality mass production and provide closed-loop

services from global delivery to long-term operational support.

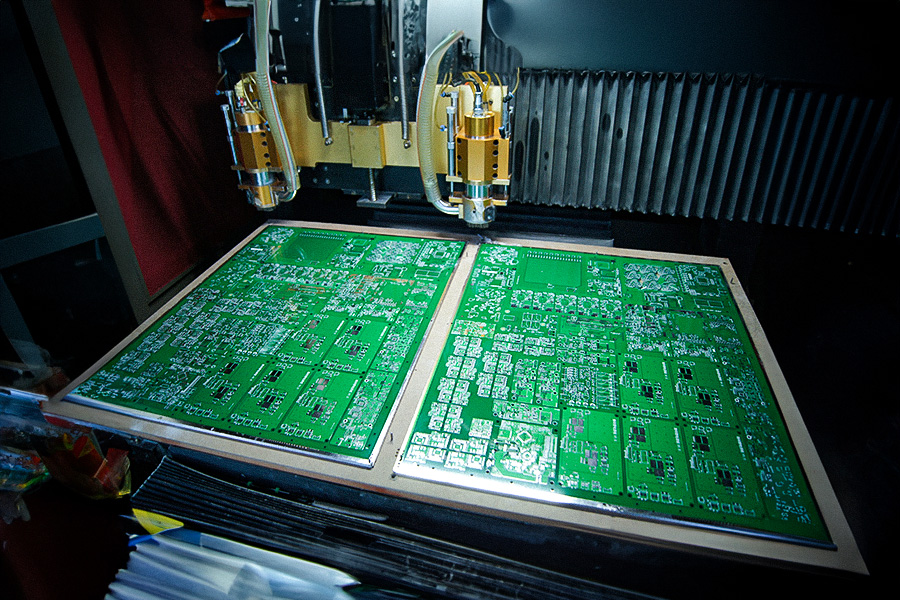

Initiating Scaled Manufacturing, Precisely Replicating Excellence

We deploy automated lines to mass-produce the golden standard prototype into consistent, high-quality units. This converts design excellence into scalable production, ensuring perfect replication.

✅ Production Ramp-up & Optimization: Debug lines & optimize cycle times to boost efficiency

✅ MES Deployment: Deploy MES for real-time production tracking

✅ Supply Chain Collaboration: Collaborate with suppliers for JIT delivery

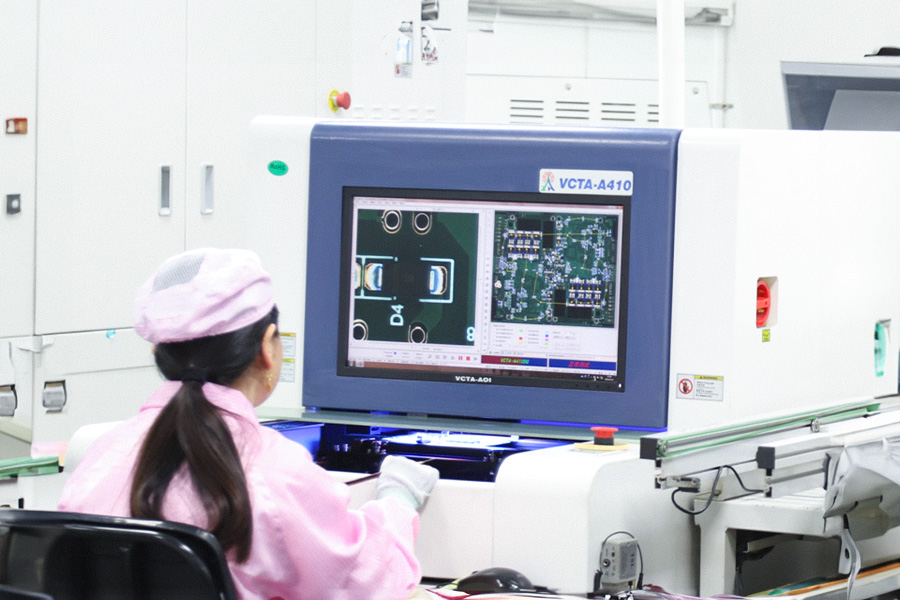

Zero-Defect Quality Product Lifeline Guardianship

We implement a multi-layered quality firewall, from components to final assembly, using automated inspection. This system eliminates defects pre-delivery, ensuring zero-defect standards for end-users.

✅ Micro-Assembly Validation (AOI/X-ray): 100% inspect solder joints & component alignment

✅ Board-Level Electrical Test (ICT): Verify PCBA electrical connections via ICT

✅ Full-System Functional Test (FCT): Simulate real-world scenarios for performance

Crossing Borders, Building a Seamless Global Delivery System

We deliver end-to-end logistics from factory to customers, integrating warehousing, shipping, customs, and last-mile delivery. This removes global supply chain complexity, ensuring safe, on-time, compliant worldwide delivery.

✅ Int’l Std Packaging & Certification: Design ISTA-compliant secure packaging solutions

✅ Global Customs Compliance: Handle customs docs & import permits for target markets

✅ End-to-End Shipment Tracking: Offer multimodal transport with full visibility

Beyond Delivery, Becoming Your Product’s Lifecycle Technology Partner

Our partnership continues post-delivery with technical support, firmware updates, and iterative planning. As your product’s long-term guardian, we use data-driven insights to enhance UX and market vitality.

✅ Global Multilingual Support: Provide rapid professional issue diagnosis

✅ FOTA Services: Remotely deploy features via secure FOTA

✅ Data-Driven Iteration: Leverage post-sales data for next-gen upgrades

Turn Your Al Vision into a

Blueprint for Success

Clarify Your Vision: Systematically structure and refine your product concept.

Get an Expert Preview: Receive a complimentary, professional feasibility assessment from our engineering team.

Define a Clear Path: Obtain a tailored roadmap proposal to bring your idea to life.

Have a groundbreaking idea for an Al product? Don’t let it remain just a concept.Our carefully designed questionnaire

helps you clearly outline your vision in minutes. This isn’t just your first step toward success; it’s the starting point for

us to conduct a complimentary preliminary evaluation and map out a clear path to realization for you.